Machining & Fabrication on the Central Coast

Request A Call Back

Thank you for contacting Berkeley Vale Hydraulics .

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Central Coast Machining and Fabrication

Need a custom part made to spec? Looking for reliable repair or rebuild solutions for your hydraulic equipment? At Berkeley Vale Hydraulics, we provide expert machining and fabrication on the Central Coast to support your systems with precision-built components and structural solutions that last.

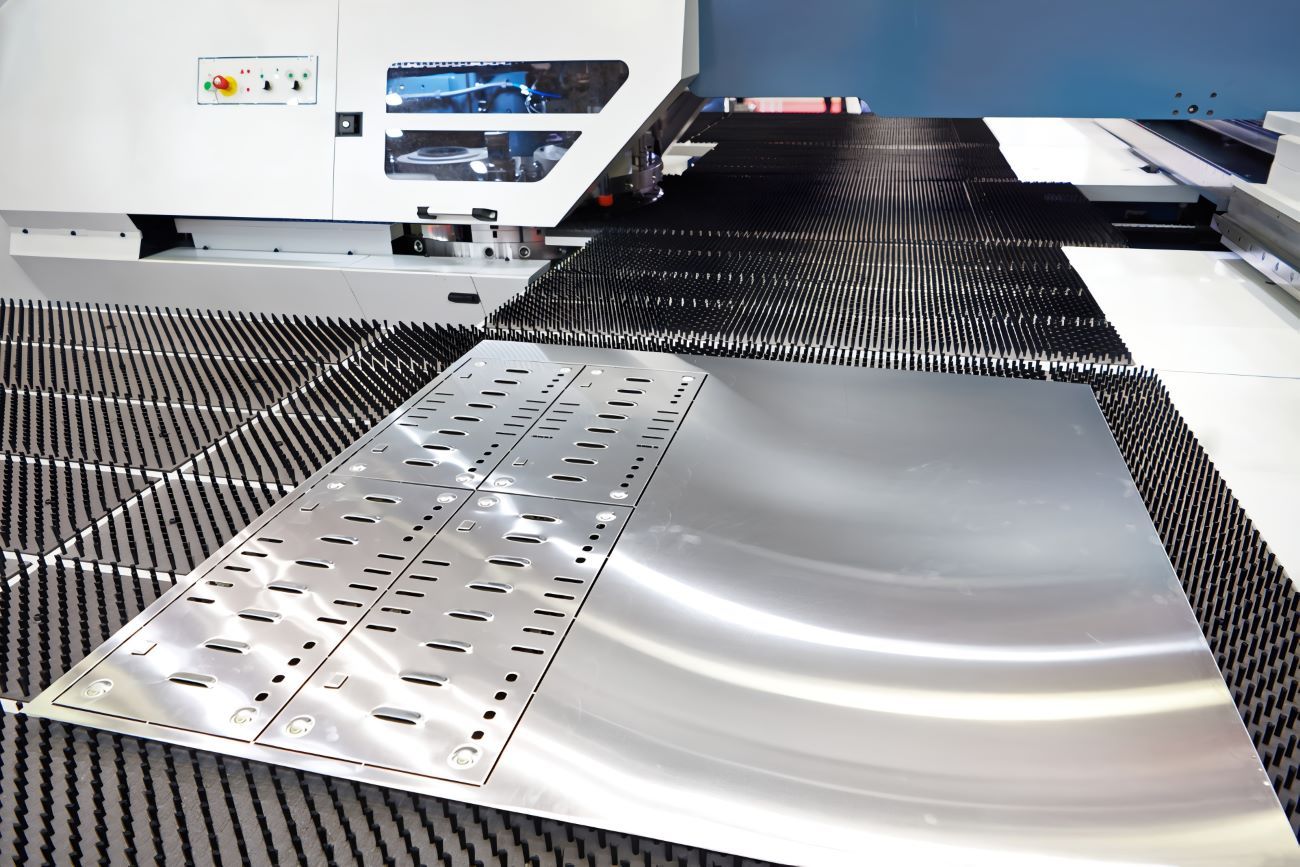

Our fully equipped Fountaindale workshop handles a wide range of work — from skimming and boring to welding, cutting, and structural fabrication. We machine and fabricate parts including control valves, couplings, crimpers, directional control valves, gear pumps, and hoists. Whether you're replacing worn components or building something from scratch, we work to your exact requirements.

We support industries across Fountaindale, Tuggerah, Gosford, Wyong, and surrounding areas with dependable workmanship and fast turnaround times. Every job is completed with care, accuracy, and a practical approach that ensures results you can rely on. Call us at 0417 983 174 to discuss your machining or fabrication needs today.

Our Machining Process

Our approach to machining and fabrication on the Central Coast is built around precision, efficiency, and practical outcomes. Every job we complete follows a clear and consistent process to ensure accuracy and reliability from start to finish:

1. Initial assessment and measurements: We inspect the component or drawing to determine dimensions, tolerances, and material requirements.

2. Material selection and preparation: We select suitable metals and prepare them for machining through cutting, cleaning, or fixturing.

3. Precision machining operations: We carry out turning, milling, boring, or drilling to meet the exact specifications needed.

4. Quality control and testing: Every part is measured and tested against tolerances to ensure fit, performance, and durability.

5. Final finishing and assembly: We complete the job with surface finishing, threading, or welding, then assemble if required.

This structured process ensures reliable results for all machining and fabrication on the Central Coast.

Speak with our team to get your custom job underway.

What materials are commonly used in machining and fabrication?

Common materials include mild steel, stainless steel, aluminium, brass, and cast iron. The choice depends on strength, corrosion resistance, weight, and operating conditions. Some applications may require plastics or specialised alloys for durability or specific mechanical properties.

Can worn or damaged parts be machined?

Yes, worn parts can often be re-machined to restore their original dimensions or performance. Alternatively, new parts can be machined based on measurements or drawings, making it possible to replace obsolete or damaged components.

How long does a custom machining job take?

Timeframes vary depending on complexity, material availability, and current workload. Simple machining tasks may take a few hours, while complex or large-scale projects could take several days. A clear timeline is usually provided after scoping.