Engineering Services on the Central Coast

Request A Call Back

Thank you for contacting Berkeley Vale Hydraulics .

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Central Coast Engineering Services

Tackle complex mechanical challenges with confidence through our expert engineering services on the Central Coast. At Berkeley Vale Hydraulics, we provide tailored solutions for industrial, transport, agricultural, and manufacturing applications. From custom hydraulic systems to structural components, we design and deliver practical outcomes built to perform under pressure.

Our in-house capabilities include CAD design, welding, machining, and full fabrication. We work closely with you to understand your needs and deliver engineered results that meet strict performance, safety, and durability standards. Every project is approached with precision, clear communication, and a problem-solving mindset.

We support clients throughout Fountaindale, Tuggerah, Gosford, Wyong, and surrounding areas. Whether it’s a one-off prototype or a full system overhaul, we bring experience, efficiency, and quality to every stage. Call us at 0417 983 174 to speak with our team about your next project.

Precision Engineering for Your Project Requirements

When it comes to reliable and efficient engineering services on the Central Coast, you need a team that understands your equipment and delivers precise, practical results. Here’s why we’re the right choice for your next project:

1. Custom Solutions Every Time: We tailor every design and fabrication to suit your specific needs and equipment setup.

2. In-House Capabilities: Our workshop handles everything from CAD design to welding and machining under one roof.

3. Industry-Focused Approach: We understand the demands of construction, transport, agriculture, and manufacturing environments.

4. Quick Turnaround Times: We prioritise efficient project delivery without compromising on quality.

5. Clear, Practical Communication: We keep you informed at every stage and deliver straightforward, effective solutions.

These points reflect our commitment to delivering high-quality engineering services on the Central Coast that support your productivity. Call us today to discuss your project with our experienced team.

What materials are used in hydraulic component fabrication?

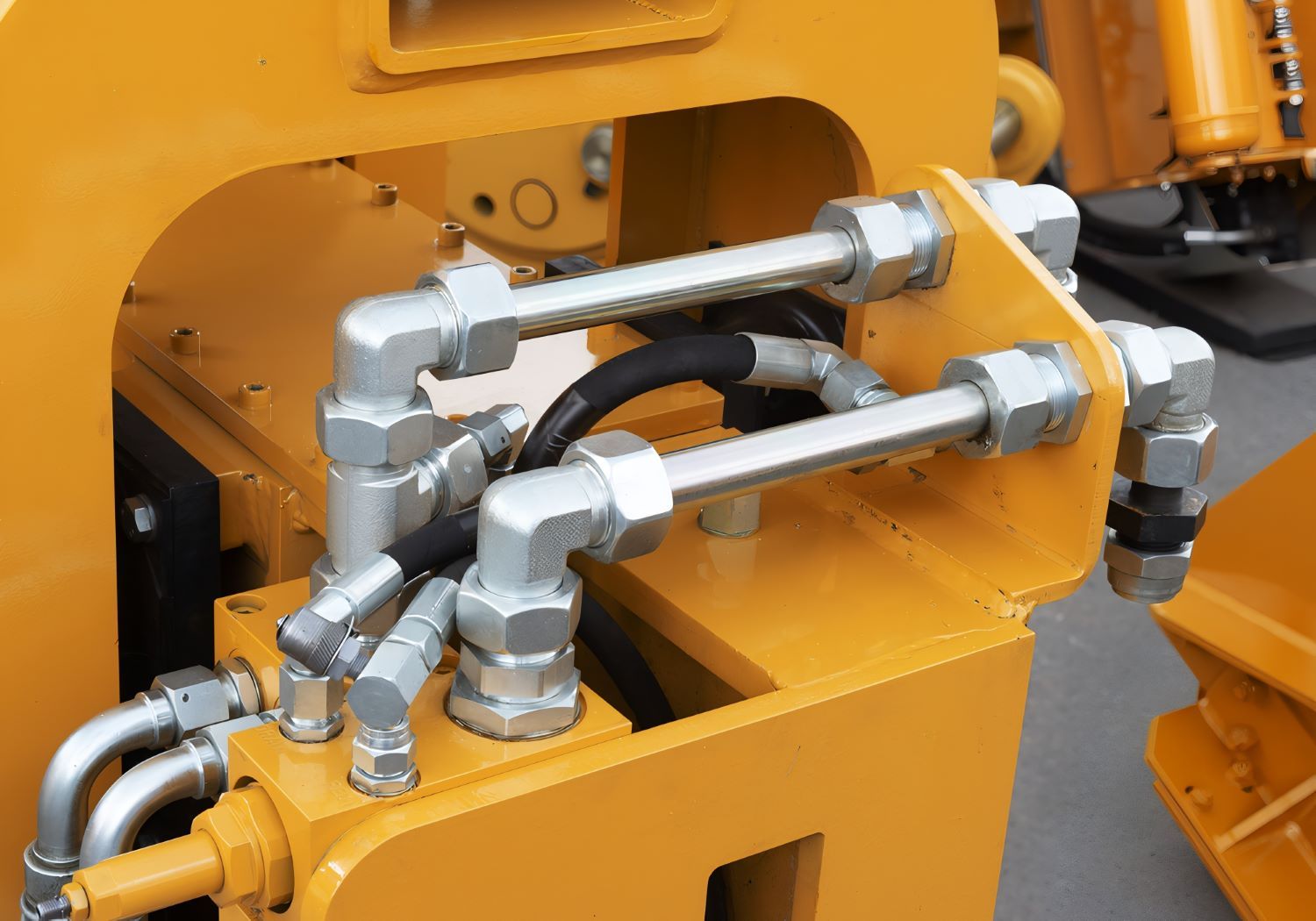

Common materials include mild steel, stainless steel, aluminium, and hydraulic-grade alloys. The selection depends on pressure rating, corrosion resistance, and environmental exposure. Engineering ensures correct material choice to suit your application.

What’s involved in hydraulic system modification?

System modification may involve re-routing lines, installing new valves, changing flow controls, or adjusting mounting brackets. Engineering input ensures changes are safe, effective, and compatible with existing components or machinery.

Do engineering services include welding for hydraulic systems?

Yes, welding is often required for mounting, structural frames, cylinder tubes, and valve blocks. Welding must meet hydraulic-grade standards to handle pressure and prevent leaks or fatigue failure over time.